EnCata provides jigs and fixture design and manufacturing services. We create custom drill bushings, jig plates, building ways, fixtures for assembling and welding.

Jigs and fixtures are useful tools to achieve the precision and effectiveness of your production process. They save time and money with the help of standardizing the processes and obtaining repeatable results. The other significant benefit is labor safety. Jigs and fixtures reduce the risks of damage to you and your employees. We often use jigs at EnCata to produce high-quality prototypes. Jigs help eliminate errors during cutting, welding, drilling, finishing, and assembling.

Fixtures are critical manufacturing tools for automated manufacturing processes. Welding and assembling with robots are impossible without well-designed fixtures. A prime example is a fixture in which a block of steel is clamped inside a CNC milling machine. If you want to put a special semi-manufactured article in a CNC milling machine, you need a custom fixture design.

We act as your extended R&D team which is faster than hiring engineers locally. The breadth of our technical expertise is unique.

Our dedicated team is ready to scale up quickly. We utilize AGILE lean development process that leads to 30-50% faster delivery.

Our development location enables us to be cost-effective and deliver premium R&D and engineering services at 1/3 of the price compared to that of in N-W Europe and USA.

Jigs and fixtures are tools that you need to launch an in-house product manufacturing. They help eliminate wastes like waiting time, defects, useless motion, and over-processing. It is necessary to quantify these wastes to decide on investments before you order jigs and fixtures, it is necessary to quantify these wastes. You can start with simple jigs and fixtures for small batches or simple products. The jigs and fixtures could be more complex and expensive for high precision products or mass production.

Rapid prototyping provides new information when testing hypotheses and finds outside-the-box solutions much faster. For products built from plastics, it helps save a good amount of money related to tooling. Also, non-standard fixtures for testing products are made using rapid prototyping methods.

We help develop products that already have a physical form and exist on the market. It is impossible to prepare a product for mass production without validating the concept and conducting testing beforehand. Our mechanical engineers design small details, improve layouts of the main assemblies, and use non-standard solutions for the prototype to improve the viability of your future product.

EnCata is ready to help you in small-batch manufacturing. Low volume manufacturing is very sensitive to used equipment and tooling, COGS, and lead time. Large producers are usually not flexible during negotiations on small orders. EnCata has an in-house production facility where we can prepare the first small batch, make hundreds of PCBAs, assemble products, and test them before shipment.

Using RE gives obvious benefits for any product design company. RE for product development saves from reinventing the wheel if you plan to allocate a budget properly.

However, RE is not a good idea for the main functions of a product. In this case, your product risks always falling behind your competitors.

Preparation of CAD files is a standardized procedure. Necessary equipment and tooling, COGS, and lead time could be highly affected by the several numbers in the technical documentation on your product.

We do not produce molded parts by the thousands. However, if you are finished with the design and want to start mass-producing, we can recommend a production company. We will assign an engineering team specializing in the production process to communicate with the manufacturer and solve quality issues.

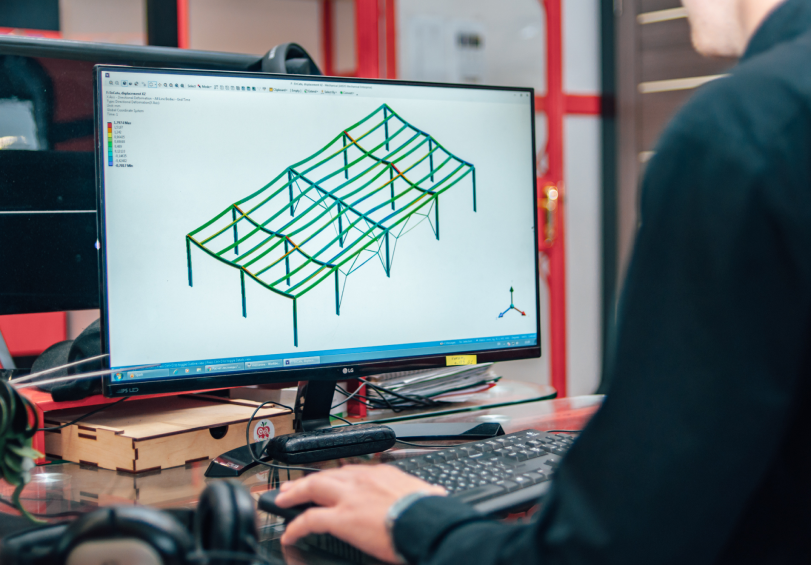

Jigs and Fixtures tooling begins with the mechanical design stage. The approach to design and manufacturing of jigs and fixtures depends on the selected production process and product requirements. Well described production process helps make calculations of each step duration. It sets up the priorities for the design team in ergonomics, durability, and maintenance. Product requirements define the tolerances which jigs and fixtures should perform. Using plastic or plywood could reduce costs, but durability and stability should still be considered.

We recommend producing prototypes of jigs or fixtures for the first batch. Further, these should be tested at the production process to uncover all quality issues to refine or eliminate. These notes will provide the needed information for any design improvements. After the design update, we will produce the final jigs or fixtures by using durable materials.

We usually use CNC machining for creating jigs and fixtures design since those are custom parts. Our manufacturing works with steel, aluminum, copper, brass, engineering plastics, and wood. When the geometry is too complex or costly for milling, we prefer 3D printing.

We focus on the entire product/service lifecycle, from concept to implementation to market launch. EnCata’s knowledge, resources and innovation development expertise allow our Clients to develop and expand their businesses faster and leaner.

EnCata can provide your startup with the end-to-end product development service in both hardware and software domains coupled with the outstanding inhouse prototyping facilities.

Turn to EnCata if you need our premimum consultancy services (concept review, design / CAD review or advice on software architecture code you produced) only when our advice is needed.

Come to EnCata with your CAD to produce parts for your prototype in EnCata. Assemble and test your prototype at our MakeIT Center fablab - we don't charge for the access!

Work that highlights the incredible technologies, solutions, and products EnCata developed.

View all projects

Our hardware engineers are focus on the entire product/service lifecycle, from concept to implementation to market launch. EnCata’s knowledge, resources and innovation development expertise allow our Clients to develop and expand their businesses faster and leaner.

Warehouse and fulfilment robots, Plant and Process Automation, Lean Manufacturing, Digial Twins Development, Connected Equipment, Predictive Maintanance, Industrial Computer platform

Medical devices & equipment, IoMT, Diagnostic Tools, Robotics and Precision Placement, Optical System, Medical Instruments & Consumables, Micro and Macro Fluidic Systems, Custom Rehabilitation Equipment

Smart Farming, Food Delivery Robots, Smart Agriculture and Crop Management, Sustainable Farming, Food Ribitics, Farm Apparatus Design, Farm & Irigation Automation, Agricultural Mechanization, Greeenhouse Automation, Climate Monitoring

Cut your development speed and costs by half with our in-house design, engineering, and manufacturing capabilities for breakthrough new products from just an idea phase.

Laboratory Instruments, Test Benches, Biological Storage, Microfluidics, Biological Laboratory, Spectrometers, Automated Clinical Instruments, Custom Scientific Apparatus, Pilot Plants, Chemistry Laboratory, Centrifuge, Sample Preparation

Industrial IoT gateway, Compact Industrial Box PC, SCADA automation, Performance Trackers and Sensors, Logistics, Real-time Monitoring, Retail Systems, Inventory Tracking, Production Flow monitoring, Fleet Management

EnCata works with both fixed term and agile contracts.

1. Once you have approached us with the project, we conclude the NDA and send the information to the Sales Manager for further evaluation and project planning.

2. The Sales Manager or Sales Engineer will contact you to clarify your goals, requirements and tasks to accomplish. This process is very close to business analysis. When the details are agreed with you, a cost estimate and a quotation are prepared.

3. If you accept the quotation, we will prepare a Technical design specification to document scope of work and requirements and conclude an agreement.

4. After we've signed the agreements, we'll assign you a Project Manager who will gather a project team and report on the project progress.

EnCata employs around 30 engineers with Master's and PhD degrees in electrical and industrial design, mechanical engineering, prototyping and manufacturing from European universities. Each employee is an expert in his or her field.

The majority of specialists are of middle or senior levels. Their range of influence is broad enough to encompass the entire new product lifecycle. Our specialists resolve legal and certification difficulties during the concept stage, optimize production costs during the 3D model development process and create necessary documentation for firmware support. Juniors make up only 15% of the team. They constantly upgrade their qualifications under the supervision of seniors.

EnCata is always willing to work with its client. We have everything we need to create a collaborative site. Both parties can work on the project simultaneously. The Customer, for instance, and his/ her team designs the electronics while we work on the enclosure. When teams work together to achieve a fantastic result, it is always a win scenario.

EnCata’s team is always willing to discuss all the necessary details about the project proposed. Our full-fledged team of professionals will interrogate you until both parties are satisfied with the procedures necessary to complete the job.

It certainly can. For any product, EnCata creates a design documentation package and a process documentation package that is suited to the production. It should be noted, however, that the technologists at the customer's chosen plant may make changes or impose their own requirements on the documentation design. EnCata, in turn, makes it easier for the client and the technologist to communicate. EnCata does not mass produce, although it can undertake small-scale production at the request of customers.

Yes. As a highly professional design and engineering firm, we make sure that all discussions with our clients and all information regarding your invention, idea and other proprietary information are kept confidential.

We follow a LEAN approach in product and business development and thus we strongly recommend patent filings only after you are at least part-way through development. This is because patenting is expensive and early patents can already become obsolete or irrelevant later in the development phase. Typically, EnCata's work generates many patentable opportunities for our clients and the best strategy is to file patents at TRL-7, i.e. when early beta prototype is ready and when a startup is ready to start batch production and marketing.There is, however, another strategy, which is to use provisional patents which can be loose and are not to be disclosed to the public for 18 months. These are much less expensive and time consuming, generally costing below $500.

EnCata will always sign a Non-Disclosure Agreement and keep your intellectual property confidential during the development phase and then we can recommend several third-party patent attorneys when the time is right.

Our in-house professionals handle almost all electronics work, including interface design, protocol development, communication design, schematic design, PCB Design, Firmware design and battery management. If the Customer requires a service that Encata does not supply, we have partners that can meet that need.

We certainly do. EnCata employs electronics specialists who deal with low-level firmware. We also have experts on staff who can implement high-level software code.

EnCata employs 12 mechanical and industrial designers and 10 electrical engineers with experience in hardware and firmware. Our team consists of middle and senior level engineers, who have 5+ years of field expertise and have already completed more than 300 projects.

We do indeed help with fundraising through our large business network. However, we typically recommend startups to our partner VCs after we have done some work for the startup and learned more about the team and their core technology. This feedback and recommendation is of great value to all of the friendly VCs as it saves them much time and effort for due diligence.